Embroidering electric power-generating yarns onto cloth has authorized researchers to embed a self-driven, numerical contact-pad and movement sensors into clothing. The strategy presents a lower-value, scalable opportunity strategy for generating wearable gadgets.

“Our method takes advantage of embroidery, which is pretty simple—you can stitch our yarns directly on the fabric,” explained the study’s lead writer Rong Yin, assistant professor of textile engineering, chemistry and science at North Carolina Condition University. “In the course of fabric output, you do not require to consider everything about the wearable equipment. You can integrate the power-building yarns just after the clothes item has been built.”

In the study published in Nano Power, researchers tested multiple styles for electrical power-creating yarns. To make them strong more than enough to endure the rigidity and bending of the embroidery stitching method, they in the end used a grouping of 5 commercially accessible copper wires, which had a slim polyurethane coating. Then, they stitched them onto cotton material with yet another material called PTFE.

“This is a very low-price tag process for building wearable electronics using commercially available solutions,” Yin stated. “The electrical properties of our prototypes were comparable to other types that relied on the exact same ability generation system.”

The researchers relied on a technique of generating electrical power named the “triboelectric effect,” which requires harnessing electrons exchanged by two unique components, like static electric power. They observed the PTFE fabric experienced the ideal effectiveness in terms of voltage and recent when in get in touch with with the polyurethane-coated copper wires, as as opposed to other forms of material that they examined, including cotton and silk. They also examined coating the embroidery samples in plasma to improve the outcome.

“In our style and design, you have two layers—one is your conductive, polyurethane-coated copper wires, and the other is PTFE, and they have a gap between them,” Yin stated. “When the two non-conductive components occur into get in touch with with just about every other, 1 materials will drop some electrons, and some will get some electrons. When you hyperlink them together, there will be a present-day.”

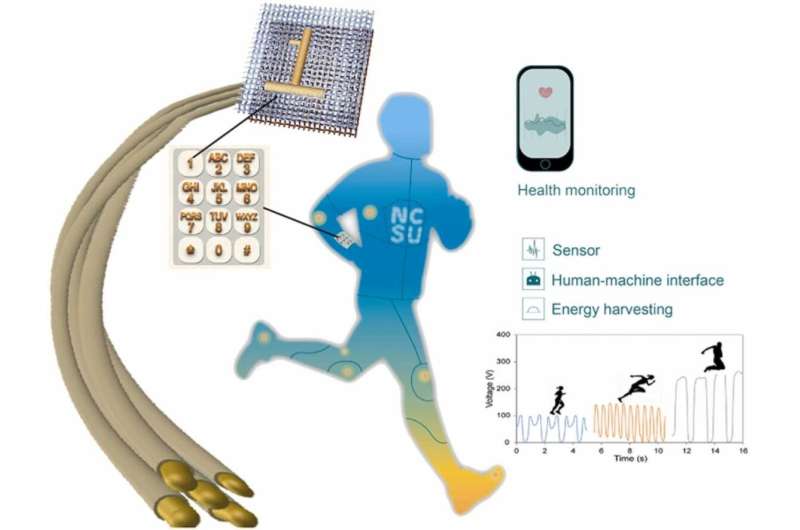

Scientists tested their yarns as movement sensors by embroidering them with the PTFE fabric on denim. They positioned the embroidery patches on the palm, under the arm, at the elbow and at the knee to observe electrical signals produced as a person moves. They also attached fabric with their embroidery on the insole of a shoe to take a look at its use as a pedometer, discovering their electrical indicators varied based on irrespective of whether the human being was going for walks, running or jumping.

And lastly, they examined their yarns in a textile-based mostly numeric keypad on the arm, which they produced by embroidering figures on a piece of cotton fabric, and attaching them to a piece of PTFE material. Based on the amount that the person pushed on the keypad, they noticed diverse electrical alerts produced for each and every range.

“You can embroider our yarns on to clothing, and when you go, it generates an electrical signal, and all those indicators can be used as a sensor,” Yin explained. “When we place the embroidery in a shoe, if you are jogging, it generates a larger voltage than if you had been just walking. When we stitched quantities on to fabric, and press them, it generates a distinctive voltage for each individual amount. It could be applied as an interface.”

Considering the fact that textile merchandise will inevitably be washed, they analyzed the longevity of their embroidery design in a collection of washing and rubbing assessments. Right after hand washing and rinsing the embroidery with detergent, and drying it in an oven, they found no difference or a slight boost in voltage. For the prototype coated in plasma, they observed weakened but however top-quality performance when compared with the authentic sample. Right after an abrasion check, they discovered that there was no considerable change in electrical output effectiveness of their styles immediately after 10,000 rubbing cycles.

In future do the job, they strategy to integrate their sensors with other units to add more features.

“The next stage is to combine these sensors into a wearable system,” Yin stated.

Study co-authors incorporated Yu Chen, Erdong Chen, Zihao Wang, Yali Ling, Rosie Fisher, Mengjiao Li, Jacob Hart, Weilei Mu, Wei Gao, Xiaoming Tao and Bao Yang.

Yu Chen et al, Versatile, tough, and washable triboelectric yarn and embroidery for self-driven sensing and human-equipment interaction, Nano Energy (2022). DOI: 10.1016/j.nanoen.2022.107929

Citation:

Researchers eye embroidery as lower-expense remedy for earning wearable electronics (2022, November 22)

retrieved 2 December 2022

from https://techxplore.com/news/2022-11-eye-embroidery-reduced-expense-remedy-wearable.html

This doc is issue to copyright. Aside from any truthful working for the objective of private study or analysis, no

portion might be reproduced without the need of the prepared authorization. The written content is provided for info needs only.