Around the previous several yrs, content scientists and electronics engineers have been hoping to fabricate new adaptable inorganic products to create stretchable and highly performing electronic products. These products can be based mostly on distinct styles, this sort of as rigid-island energetic cells with serpentine-condition/fractal interconnections, neutral mechanical planes or bunked structures.

In spite of the major progress in the fabrication of stretchable materials, some issues have proved hard to overcome. For instance, materials with wavy or serpentine interconnect styles typically have a restricted area density and fabricating proposed stretchable components is usually equally tough and highly-priced. In addition, the stiffness of many existing stretchable materials does not match that of human skin tissue, producing them uncomfortable on the skin and as a result not excellent for making wearable technologies.

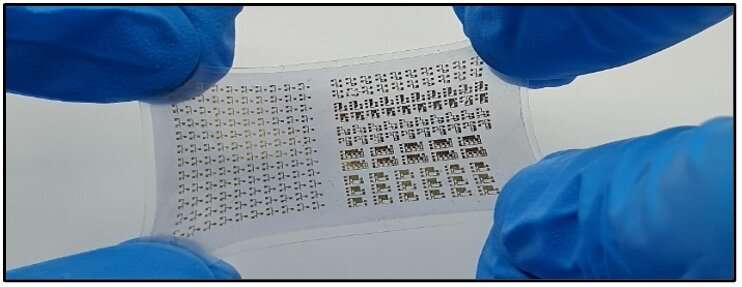

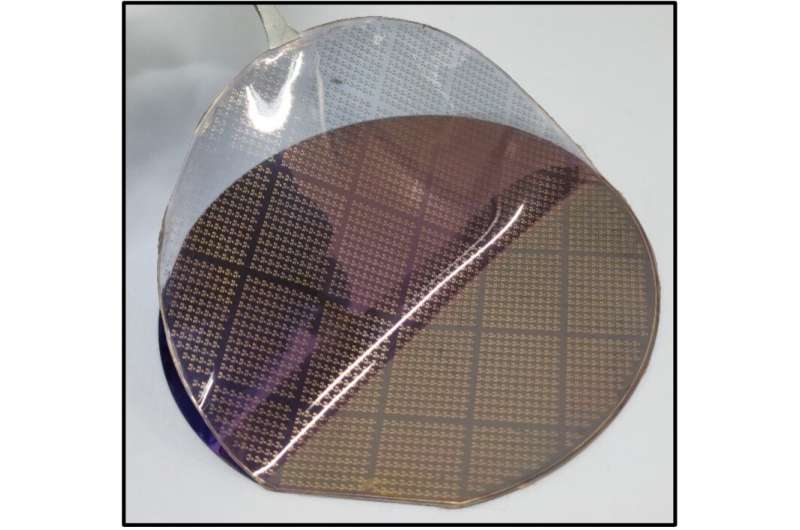

Scientists at Sungkyunkwan University (SKKU), Institute for Primary Science (IBS), Seoul Countrywide University (SNU), and Korea State-of-the-art Institute of Science and Technology (KAIST) have not long ago fabricated a vacuum-deposited elastic polymer for building stretchable electronics. This materials, released in Nature Electronics, could be applied to create stretchy discipline-outcome transistors (FETs), which are primary elements of most digital units on the market place these days.

“Just lately, a variety of techniques for adopting smooth supplies have been proposed for creating intrinsically stretchable electronics which does not require any particular structural layouts owing to their intrinsic deformability,” Donghee Son, one of the scientists who carried out the review, told Tech Xplore. “Nonetheless, this sort of gadgets utilized option-processed dielectric products and therefore face significant issues in accomplishing superior electrical performances.”

Remedy-processed organic and natural gate dielectric supplies, materials that can transmit electric power without the need of conducting it (i.e., insulating it), are not particularly suited for the generation of versatile electronics. Most notably, they have thicknesses in the micrometer-scale, very poor insulating performances, chemical instability and a small uniformity. In addition, they are normally incompatible with conventional microfabrication processes, building them tricky to develop on a large scale.

As a outcome of these restrictions, electronic factors dependent on these option-processed components are plagued by weak gate controllability and significant procedure voltages, as perfectly as a limited scalability. Son and his colleagues, together with other research groups throughout the world, have so been striving to make ultrathin, stretchable, scalable, and remarkably accomplishing dielectrics with option fabrication strategies.

“In our examine, we existing a new method to the design and style of dielectric products to take care of the aforementioned difficulties in intrinsically stretchable digital devices,” Son discussed. “Our significant-scale vacuum-deposited stretchable dielectric allows the scalable fabrication of intrinsically stretchable devices with electrical performances equivalent to all those fabricated applying the non-stretchable inorganic and stretchable organic dielectric elements (e.g., Al2O3 deposited by means of atomic layer deposition & spin-coated viscoelastic layer).”