BOSTON, Might 5, 2023 /PRNewswire/ — Smooth, practical surfaces that give touch sensing, frequently with backlighting, are turning out to be ever more common. Purposes selection from vehicle interiors and domestic appliances to medical equipment and aircraft seating. Fairly than relying on a mechanical or membrane change, these surfaces employ capacitive touch sensing – the same principle used in smartphone shows. Capacitive sensing and backlighting of training course require electronics powering the ornamental exterior floor: in-mold electronics is an emerging producing technique that guarantees to make practical surfaces less expensive, lighter, and extra aesthetically satisfying.

What Is In-Mould Electronics?

As the identify suggests, in-mold electronics (IME) is a manufacturing process in which at minimum some of the electronics are subjected to a molding approach. Generally, this begins with display screen printing the ideal sample of conductive ink on to a substrate (often polycarbonate) – these conductive designs allow capacitive touch sensing. Subsequent, a attractive layer is utilized to the entrance, and the conductively patterned substrate is thermoformed to produce the demanded curvature. A subsequent injection molding phase is often applied. This solution of integrating electronics into the molded section contrasts with regular electronics production procedures, in which attractive user-struggling with elements would be molded, and a printed circuit board (PCB) mounted on to the back again afterward.

Why hazard subjecting the electronics to this molding method when a PCB powering a attractive surface would typically suffice? Based on the strategy used, IME enables a weight and content usage reduction of up to 70% relative to conventional mechanical switches. Also, given that much less particular person elements are expected, the two assembly and connected offer chains can be simpler. Offered these benefits, along with escalating engagement from each suppliers and integrators, IDTechEx forecast the sector for IME pieces that incorporates SMD (floor mount product) factors to attain close to US$2bn by 2033.

What Are the Competing Ways?

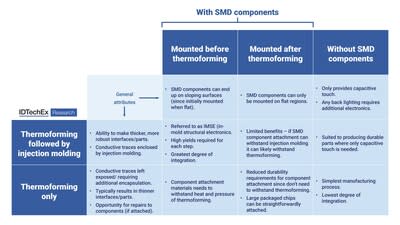

In the umbrella expression of ‘in-mildew electronics’, there are quite a few subtly various producing techniques. Establishing which tactic has been used is usually tricky due to the fact the resulting useful surfaces appear particularly very similar. Two critical variables are regardless of whether and at what level SMD parts these as LEDs are mounted, and whether injection molding is used.

Arguably the most thorough approach to IME, designed by Tactotek and termed IMSE (in-mildew structural electronics), requires mounting SMD components on a flat substrate prior to thermoforming. This is adopted by injection molding, embedding the elements and conductive traces in plastic. The system final results in a strong component with fully enclosed electronics, probably which includes an built-in circuit.

A competing strategy is to mount the SMD factors onto an currently thermoformed part and neglect the injection molding. This calls for a thicker polymeric substrate to offer enough rigidity, which usually lowers the diploma of distortion and curvature that can be released via thermoforming. Furthermore, SMD parts can only be mounted via decide and location on locations that keep on being flat. Nonetheless, for several purposes, only slight curvature all over the perimeter or in other precise destinations is required, and since mounted components will not be subjected to the heat and force connected with molding substance specs and style regulations may perhaps be extra forgiving.

The easiest tactic to IME is to omit the SMD components completely. Ornamental surfaces with built-in capacitive contact can be made relatively straightforwardly by initially screen printing conductive ink then thermoforming the substrate. Subsequent injection molding is optional. Whilst these pieces would require typical electronics for backlighting, they depict an intermediate stage between purely attractive and fully purposeful surfaces that can meet the desires of easier use situations.

What Does the Long term Maintain?

The extensive selection of competing producing ways to in-mould electronics does not indicate a Darwinian scenario with only 1 winner – just about every approach delivers a diverse balance of price tag, variety factor complexity, performance, robustness, and measurement/weight reduction that can fulfill a unique need. General, IDTechEx envisages a gradual craze to larger performance integration considering the fact that it features the most scope content and weight reduction but with bigger adoption barriers than more simple manufacturing methods.

How Do I Find out Much more?

IDTechEx’s new report, ‘In-Mold Electronics 2023-2033‘, draws on over 20 organization profiles, the majority based mostly on interviews, to investigate this emerging producing methodology. This complete report evaluates the technological procedures, content requirements and programs. It features 10-year marketplace forecasts by production methodology and application sector, expressed as the two profits and useful surface area region. Furthermore, the report presents a thorough evaluation of competing strategies, these kinds of as purposeful movie bonding and the merits of such as elements these kinds of as LEDs in just the IME areas.

To find out far more, together with downloadable sample web pages, remember to visit www.IDTechEx.com/IME.

Writer: Dr Matthew Dyson, Principal Technologies Analyst at IDTechEx

About IDTechEx

IDTechEx guides your strategic business decisions as a result of its Investigation, Subscription and Consultancy items, serving to you gain from rising technologies. For more data, get hold of [email protected] or pay a visit to www.IDTechEx.com.

Illustrations or photos Download:

https://www.dropbox.com/scl/fo/qugtvyrfr3d31e9b6gsoq/h?dl=&rlkey=pp9rky0nk7sc66lc55jffwpu8

Media Contact:

Lucy Rogers

Profits and Marketing Administrator

[email protected]

+44()1223 812300

Social Media Links:

Twitter: www.twitter.com/IDTechEx

LinkedIn: www.linkedin.com/firm/IDTechEx

Fb: www.facebook.com/IDTechExResearch

Image: https://mma.prnewswire.com/media/2065304/Sorts_of_IME.jpg

Symbol: https://mma.prnewswire.com/media/478371/IDTechEx_Brand.jpg

Check out authentic written content to down load multimedia:https://www.prnewswire.com/news-releases/idtechex-unravels-competing-in-mildew-electronics-manufacturing-methodologies-301810453.html

Resource IDTechEX